MATERIAL MATTERS

The Material Matters exhibition at the 2023 London Design Fair was a space created to showcase a

whole range of innovative and sustainable new material possibilities. Travelling through its four floors, a range of brands, designers and interesting materials were put on display, all with a different story of how and why they came to be. Some beautiful pieces of design and inspiring fresh materials were on display, however, as I traversed up the levels, I felt at points that some of these showcases felt more like advertisements. Don’t get me wrong, all of the brands and designers on display were doing commendable things with interesting materials and top class design work, so perhaps it was the ongoing

‘networking’ that felt out of place with the more relaxed and

individual student experience I’m used to.

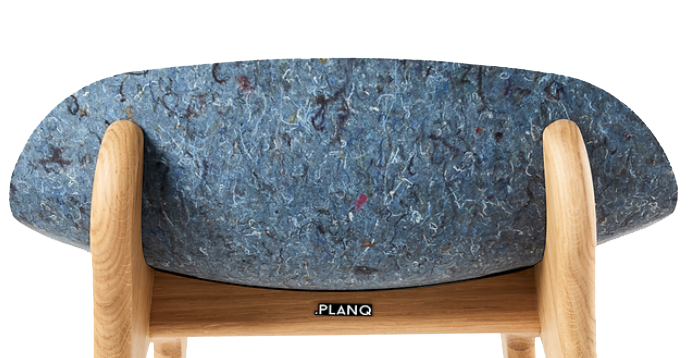

PlanQ design showcase

When I did reach the top floor however, I found myself talking at length with

Anthony Gray from ‘PlanQ’, at first about his product but eventually on his opinions of the exhibition as a whole. This conversation rationalised what I was thinking, as he spoke at length about how he found a few of the brands downstairs were prone to using a ‘sustainable selling point’ which in reality had

actually came as more of an afterthought

For example, the luxury British lighting design company, Bert Frank,

whose place in the exhibition somewhat confused me. Other than some very interesting use of jesmonite’s

translucency as a natural diffuser in the ‘Beran’ range, the materials used in their products could be described only as high quality, not innovative, and the space the exhibition had reserved for them seemed closer to a product showroom, complete with catalogues. I wasn’t surprised then, after I had left the exhibition, to find Bert Frank described as “Our headline sponsor” on the Material Matters website.

Bert Frank’s ‘Beran’ Light

The industrial lighting fixtures sold by Bert Frank are no doubt examples of exquisite industrial design,

which is why it felt so awkward within the exhibition to focus on the product’s supposed recyclability. This is a product sold at a top end price point, handmade in small batches and described as being “enduring quality, built to last a lifetime”. In this scenario, where products are made to an undeniably high and enduring standard, a focus on repairability rather than lacklustre material recyclability would feel more appropriate and I think that’s why this ‘showroom-esque’ display felt to me so insincere. Despite this, no matter what the motives,

any company willing to sponsor an exhibition of so many up and coming sustainable designers

and brands is hard to criticise. Perhaps I need to allow my student mindset to become more corporate.

Perhaps I need to start Networking.

In contrast to this, what I would describe as

the pinnacle of eco-material design showcased in the exhibition came from ‘The Tyre Collective’, a team prototyping a rear wheel mounted product tasked with collecting the pollution produced by vehicle’s tyre wear. As well as this, a range of materials produced with the rubber by-product had been displayed, all with varying properties and potential applications.

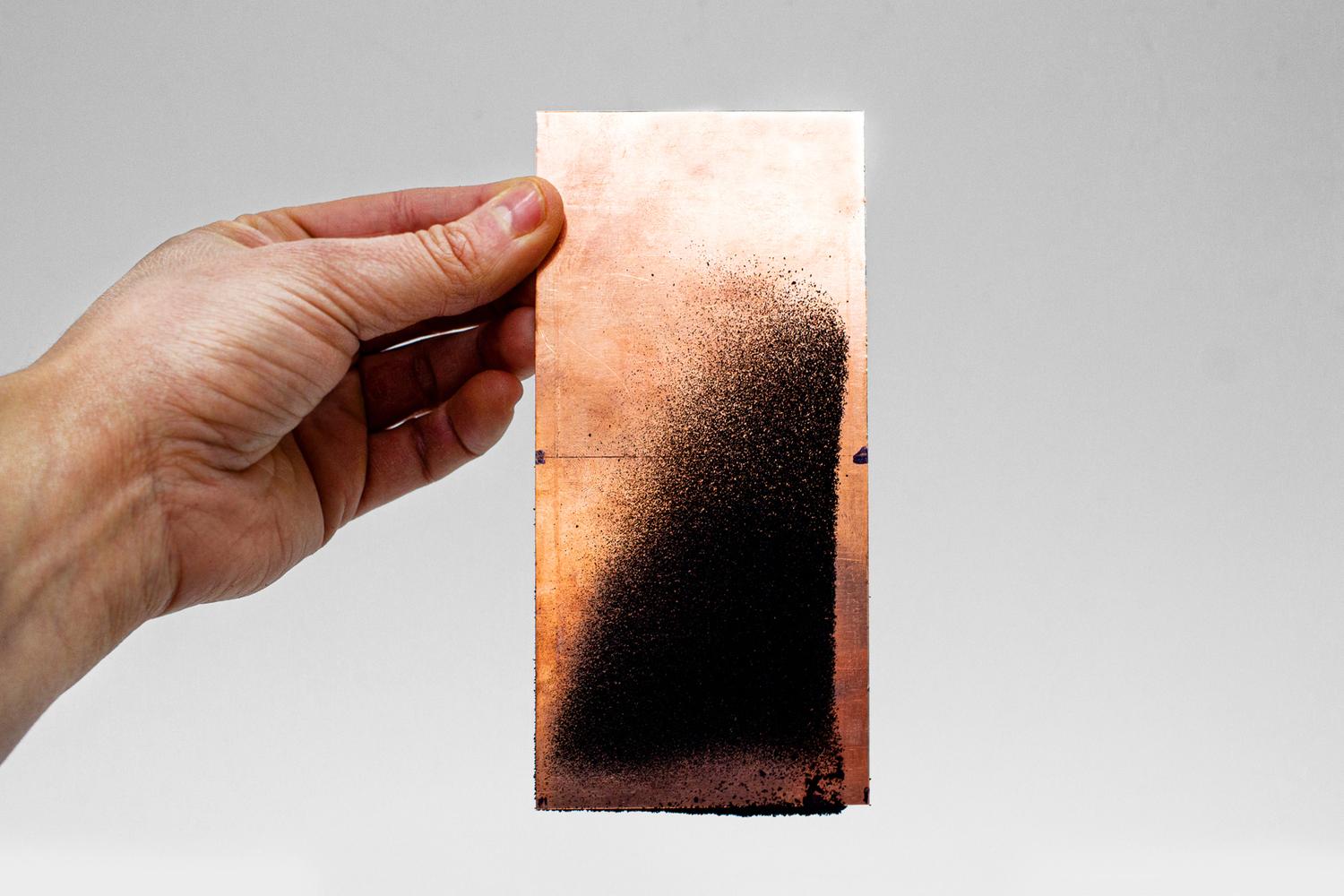

The Tyre Collective’s sample capture sheets

For me, the Tyre Collective design’s merit comes from the fact they have

targeted and addressed a specific problem. Statistics plastered across the wall stated

“Tyre wear is the second largest source of ocean microplastics” and “the No1 air pollutant in central London” and small boxes on the table contained shocking samples of the average volume of rubber released by a variety of vehicles in a single day's use. By addressing something that is clearly a large issue and finding a solution that not only resolves it but creates a valuable material by-product, they achieve a material that may be referred to as truly carbon positive. In this way I see the Tyre Collective as a prime example of sustainable design. Their design solution, a word used frequently throughout the exhibition, actually emerges from a problem.

Contrasting this were brands such as ‘Mater’, ‘PlanQ’ and ‘Solidwool’ or designers

‘Tanja Kirst’ and ‘Tamasine Osher’. Rather than having a sole focus on sustainability, these brands instead showcased the beauty innate within their biologically derived materials as a feature to enhance their designs. I’ve always been drawn by woodwork that makes a feature of the natural grain, so seeing a range of new naturally produced materials that all have their own ‘grain’, texture and imperfection similar to wood opens up a range of new material possibilities and inspiration for me.

Kirst’s woven rugs

Kirst’s woven rugs are made from natural yarns spun from items such as oranges,

seaweed and pineapple in the Netherlands. Woven as an abstraction of natural Danish landscapes, a subtle natural aesthetic is maintained within the otherwise geometric pieces by the variation in texture and colour that the yarns provide. I find the use of yarn or other natural fibres - for example, in hand stitching applications such as leatherwork - a really interesting way to incorporate more natural materials and subtle imperfection into products. This art of imperfection (the ‘wabi sabi’ Japanese philosophy) is something I have a real interest in and am looking to investigate more in future. Who knows,

it might even get its own blog post.

Osher’s hand-turned ‘Grain’ lamps use the live edge and natural chatoyancy

of the wood grain to turn an otherwise simplistic design into a piece of art which brings natural variation and

imperfection into an indoor setting. When I work with wood, this level of making the material and its natural appearance a feature of the product is the gold standard of what I aim to achieve.

Osher’s Grain Lampshades

Solidwools material and design

On the more engineering-design focused side of the exhibition were companies such as

PlanQ, Solidwool and Mater. These brands all use naturally sourced fibres from a variety of sources (jeans, wool, flax…) along with naturally derived bonding agents such as potato starch to press together and create recycled, formable plywood like materials which are fully recyclable and compostable.

In the past these design houses have primarily sold their own design work using these materials.

The majority of these sales are made to large scale office environments in order to furnish rental spaces which are usually subject to short turnarounds. However, companies such as PlanQ are moving towards a new supply model with their offshoot company ‘Rezign’ which empowers others to create with the materials they supply.

Rezign’s new materials range

Rezign’s recycled jean material

And it’s these materials, not the company's designs, that I find so exciting.

Similar to Tanja Kirst’s woven rugs, the natural fibres in the composite materials create a grain like texture

across the surface whilst the materials innate colour variation creates a matte finish with a softer natural feel than plastics or synthetic composites. With this surface finish and texture but manufacturing capabilities similar to plywood, this and numerous other materials displayed at the exhibition have supplied me with a wealth of inspiration for future material use.

.....

.....

COMMENTS:

To leave a comment, email your comment to jakabon@outlook.com with the title

of the post you wish to comment under as the email subject

Caitlin Hodgson

Ah, Mr Bon, a great piece of work.

8th Feb